Pharmaceutical products created in a cleanroom are much more meticulously developed and are of the highest standard. The production of pharmaceuticals requires maximum cleanliness and safety. Efficiency is paramount. Clean room lifting cranes, as the guardians of this field, ensure the quality and safety of pharmaceutical production with their dust-free handling and precise operation.

Advantages of Pharmaceutical Cleanroom Crane

• Strict Compliance with GMP Standards.

Pharmaceutical production follows the Global Pharmaceutical Manufacturing and Quality Management Practices (GMP), and the design and operation of clean room cranes must comply with these standards to prevent contamination and cross-contamination during the production process. This includes the use of dust-free materials, anti-static design and regular cleaning and maintenance.

• Efficient production Process

If you are manually moving materials involved in pharmaceutical production, you may end up wasting time and money - especially if you are dealing with large, heavy materials. To improve production speed and efficiency, it is recommended that you use a cleanroom crane.

A cleanroom crane is an efficient tool for handling large materials in pharmaceutical operations. With it, you will be able to move materials in a refined way, avoiding any unnecessary movements. The best part is that these cranes come with automated controls, which means you'll need to do less manual work when running a production site.

• Particle Control

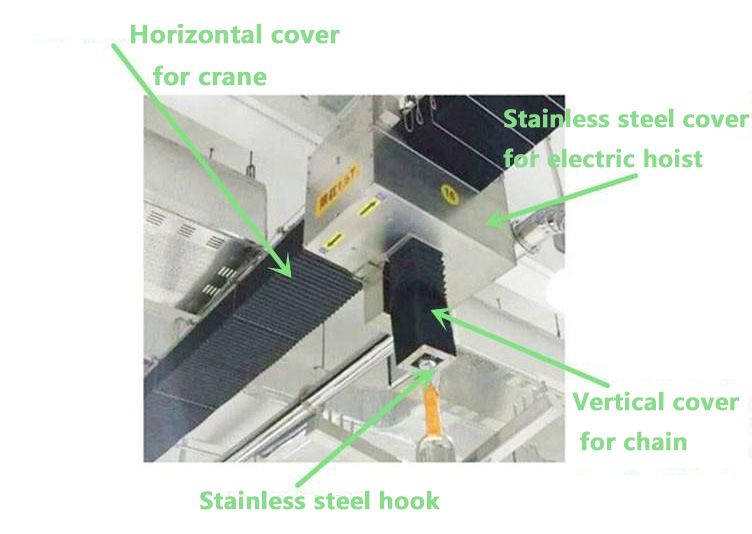

Any pharmaceutical production facility must remain sterile, whether manufacturing medicine or medical equipment. Clean room crane adopts a closed design to reduce particles generated during the handling process and ensure that materials move in a dust-free environment.

For the pharmaceutical production workshop, stainless steel is the most material used for devices, which features their high durability, easy sanitization, and high-temperature tolerance. And grade 304/316/316L stainless steel are most widely used grade in the medical industry.

In addition, silver ion coatings are the special ingredient that prevents microorganisms from growing on any surface of the crane. That's going to help you keep your materials completely sterile and thus safe throughout the different stages of product development. This design resists microorganisms and complies with pharma regulations.

• Accurate Positioning

In a pharmaceutical production environment, it's crucial to ensure safety when moving large materials to avoid any accidents. To achieve this, a hygienic lifting crane can be set up around the production area, which can significantly enhance the safety capabilities.

Cleanroom lifting crane is designed for precise movement, allowing workers to move materials to a specific location without any unnecessary movement. This significantly reduces the risk of accidents and injuries. The crane operator controls only the specific movements required, ensuring the safety of everyone on the work site.

Clean Room Crane Applications

Sound Enclosures

Equipment Enclosures

Automotive Industry

Medical Device Assembly Areas

Laboratories

Optic Industry

Nano Technology

Wafer Fab Production

Composite Industry

If you are actively involved in pharmaceutical production, there may be large or heavy materials that need to be transported to different areas. Talk to a KFCS to purchase a pharmaceutical cleanroom crane.

At KFCS, we are committed to providing our clients with the highest standard of pharmaceutical lifting solutions through advanced cleanroom technology and strict quality control processes. We understand that every detail is critical in the pharmaceutical industry, which is why we consistently adhere to manufacture cleanroom cranes with high standard.

0086-13390692151

0086-13390692151