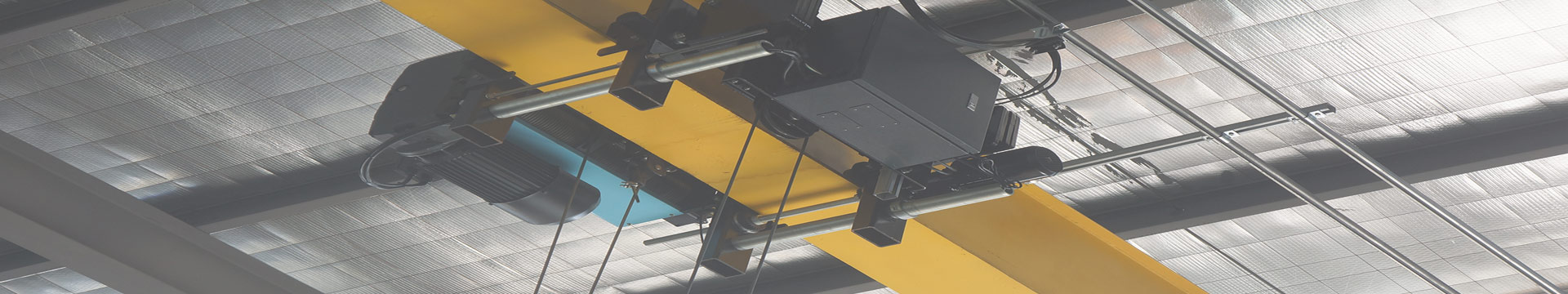

Pharmaceutical workshop purification engineering clean room crane is used in Pharmaceutical Workshop purification engineering workshop, including bridge double-beam crane for cleanroom, bridge single-beam crane for cleanroom, mobile gantry frame for cleanroom, jib crane for cleanroom, flexible KBK crane for cleanroom, etc.

So what is the main purpose of Pharmaceutical Workshop purification project construction?

The construction of Pharmaceutical Workshop purification project is mainly to control particulates and microorganisms in the purification workshop, as well as the temperature, humidity, air pressure difference, illumination, noise and other parameters in the environment of the pharmaceutical cleaning workshop, so that the dust-free workshop construction can meet the requirements of different pharmaceutical production processes and different production links to the environment and ensure the control of the environment of the pharmaceutical production workshop. There is no purpose of gases affecting the quality of medicines and human health in the environment of the biopharmaceutical production workshop.

In the 2010 edition of the specification on GMP, there is a very clear division of cleanliness level of purification engineering in pharmaceutical workshops. Biopharmaceutical workshops are divided into four levels, namely A, B, C and D, and the process parameters of each level have different requirements. Class A is a high-risk operation area, which generally needs laminar flow operating table (cover) to maintain a dust-free air environment. The laminar system in the operating area of this grade must meet the standard of uniform air supply in the working area, and the wind speed must be controlled in the range of 0.36-0.54m/s (guiding value). Data shall be provided to prove the state of the laminar flow and to verify it. In addition, one-way flow or lower wind speeds may be used alone in a sealed isolation operator or glove box in a Class A clean area. Class B clean area refers to the background area of Class A area with high risk operations such as aseptic preparation and filling. Class C and D refer to the less important clean operating areas in the production of sterile drugs.

Pharmaceutical production process in Pharmaceutical Workshop purification engineering can be divided into aseptic drug production, non-aseptic drug production, pharmaceutical raw material production and traditional Chinese medicine preparation. In Class A, B and C clean areas of biopharmaceutical cleaning workshop, there are very strict and specific requirements for static and dynamic environment, while Class D only requires static environment. Generally speaking, if there is no special requirement for temperature and humidity in the dustless chamber engineering during the production of biopharmaceuticals, the air cleanliness A (B) and C (area) temperatures in the medical cleanroom need only be controlled stably at 20-24 C and the relative humidity at 45%-60%; The air cleanliness level D is different, and its temperature control range can be wider. Generally, only the temperature needs to be stabilized at 18-26 C and the relative humidity needs to be stabilized at 45%-65% to meet the standards and requirements.

0086-13390692151

0086-13390692151