A wheel block system is a rail-mounted crane component that comprises a set of wheels and a frame to support the load during movement. The system can handle loads up to 40 tons

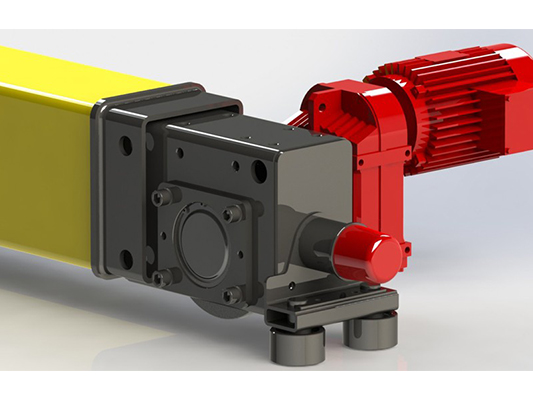

The modern, optimised DRS traveling wheel block system with its six frame sizes can be used universally. It is suitable both for manufacturing cranes and crabs and for off-standard applications. The wheels, guided by flanges on both sides, guarantee quiet, runway-preserving travel, and can in addition be equipped with guide rollers. The reliable drive options are pole-changing hollow shaft drives, frequency inverters or slimline pancake gears. Five standard configurations are available for mounting them on the customers' structures.

Technical Features

• Universal: can be used for wheel loads from 5,00 to 40,000 kg in eight frame sizes

• Flexibility: Our product offers five standard configurations that can be connected to your supporting structure according to your needs.

• Reliability: We provide multiple brands of drives to meet every requirement. Our low-maintenance direct drives are designed to ensure the highest level of reliability.

• Choice: We offer various components on request, including drives with innovative frequency inverter mounted directly on motor, to provide you with the widest possible range of options.

• Maintenance-friendliness: Our DRS wheel blocks can be easily rolled out to the front for maintenance purposes. Several bolts and installation mounts also enhance maintenance.

• Field-proven: Our series components have been tested and proven to deliver maximum performance for onsite working.

• Compactness: On request, we can provide our product with a space-saving pancake gear to meet your space requirements.

• Safety: Our product is available in an explosion-protected design in compliance with ATEX safety standards, providing you with maximum safety and protection.

Different Connections of Wheel Blocks System

A number of different mounting methods guarantee universal and extremely flexible use.

• Head connection H

The traveling wheel block is bolted on at the top.

• Welded connection W

The traveling wheel block end is welded directly to the supporting structure without any intermediate flange

• Inserted connection I

The wheel block is plugged into a hollow profile and secured with bolts.

• Screwed connection S

A connecting flange is used to bolt the wheel block end to a steel structure.

• Affixed connection A

A connecting flange is used to weld the wheel block end to a steel structure, the connection can be dismantled.

• With guide rollers

The guide rollers are mounted securely with positive-locking and can be used even with relatively flat rails.

A wheel block system is a rail-mounted crane component that comprises a set of wheels and a frame to support the load during movement. The system can handle loads up to 40 tons, and the wheels can have a diameter of up to 500 mm. Besides crane accessories, the wheels can also be deployed for moving heavy loads.

As a professional lifting solution supplier, KFCS are waiting to help you better. Welcome to contact us!