Belt load turning device is a device used to flip or rotate products on a production line.

Belt load turning device is a device used to flip or rotate products on a production line. It usually consists of a belt conveyor and a turning device, which can turn the product from one direction to another to meet the needs of the production process. Belt load turning device is widely used in food processing, foundry workshops, automobile production lines and other industries, playing an important role in the production process.

Composition structure

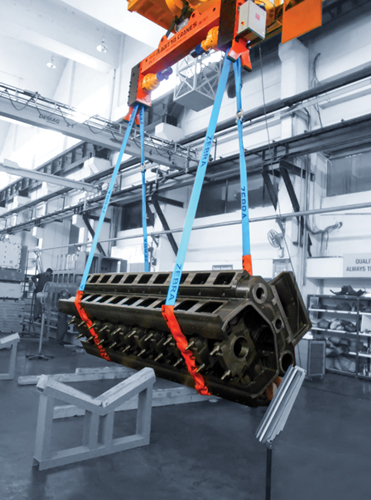

● Turning platform: It is the core part of the belt load turning device. It is usually welded with high-strength steel and has sufficient load-bearing capacity and stability. The surface of the platform is covered with anti-slip and wear-resistant materials to ensure the safety of the heavy truck chassis during the flipping process.

● Drive system: It is composed of motor, reducer and transmission chain, etc., and is responsible for providing the power for the rotation of the flipping platform. By controlling the speed and steering of the motor, the forward and reverse rotation of the flipping platform can be realized, thereby completing the flipping operation of the chassis.

● Control system: It is the intelligent center of the belt load turning device, consisting of control equipment such as PLC or touch screen. The operator can set parameters such as turning speed and time through the control system, and monitor the real-time status of the turning process to ensure the safety and accuracy of the operation.

● Safety protection device: In order to ensure the safety of the operation process, the belt load turning device is equipped with a variety of safety protection devices, such as limit switches, emergency stop buttons and overload protection. These devices can cut off the power supply in time when equipment malfunctions or abnormal conditions occur to prevent accidents.

How to realize the flipping of heavy truck chassis?

● Preparation work: Park the heavy truck chassis on the load turning device platform, ensuring that the vehicle is stable and the tires are in close contact with the platform. Operators then check the status of the equipment to ensure that all components are intact and safe.

● Start the equipment: The operator starts the belt load turning device through the control system, the driving system starts to work, and the turning platform starts to rotate slowly.

● Monitoring process: During the turning process, the operator should pay close attention to the status of the equipment and the chassis turning situation to ensure that the turning process is smooth and abnormal. If necessary, the flipping speed and direction can be adjusted through the control system.

● Complete flipping: When the chassis flips to a predetermined angle or position, the limit switch will automatically cut off the power supply and the flipping platform will stop rotating. At this point, the operator can begin inspection, repair or maintenance operations on the chassis.

● Ending the operation: After completing the chassis repair work, the operator starts the equipment again, flips the chassis back to its original position, and then drives away from the belt load turning device platform.

Design features

● The advanced drive system and control system can achieve fast and smooth chassis flipping, greatly improving the efficiency of maintenance work.

● Equipped with a variety of safety protection devices to ensure safe and reliable operation. At the same time, the design of the flipping platform also fully considers stability, effectively preventing the chassis from slipping or overturning during the flipping process.

● The compact structure and simple operation make it easy for maintenance personnel to get started quickly. At the same time, the equipment also has good versatility and can adapt to the flipping needs of heavy truck chassis of different types and specifications.

● The flipping platform is made of high-strength steel and has strong load-bearing capacity and wear resistance. The drive system and control system also use high-quality components to ensure long-term stable operation of the equipment.