Cleanroom belt hoists are protected by 304/316 stainless steel shield, which is highly resistant to wear and tear, and prevent hoists from fading and scratching. Most ss clean room hoists are applied in food and pharmaceutical industries.

It's already a big challenge to construct a clean room crane in compliance with ISO14644: 1 requirement. It's an even bigger challenge to design it so that there's no contamination from operations, cleaning, maintenance, or retrofitting with components or functions. This belt hoist is designed to meet heavy load handling in cleanrooms, with max capacity of 30 tons.

Electric belt hoist features high strength belts, which allows a high safety factor allows for quick and easy replacement. Widely applied in food, semiconductor, pharmaceutical, laboratory and institutes.

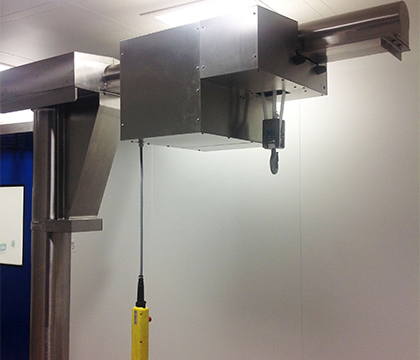

The consistently smooth surfaces make the belt hoist exceptionally easy to clean. All components, including cables, geared assemblies, screw connections, electrical components, sensors, and the electric belt hoist for the hoist, are discreetly integrated within the housing. Following are top three features of cleanroom belt hoist.

Stainless Steel Housing for Belt Hoist

When used for some industries, which requires controlled environment, our belt hoist serve the lifting in a safe and clean way. Due to the high air humidity in some special industry cleanrooms, the lifting equipment must possess sufficient corrosion resistance. Our clean room belt hoist is capable of meeting this requirement.

Cleanroom belt hoists are protected by 304/316 stainless steel shield, which is highly resistant to wear and tear, and prevent hoists from fading and scratching. Most clean room belt hoists are applied in semiconductor and pharmaceutical industries.

High Strength Load Belt

The load belt requires no maintenance whatsoever, eliminating the need for lubrication that could otherwise contaminate the clean room, unlike chain or rope. The low-wear belt material allows longer service life in corrosive environment and heavy duty works.

High Precision Control

When it comes to improved clean room belt hoist precision through good platform, it is above all the PLC that scores. Thanks to the PLC component, an upgrade to a touchless and millimeter-precise position sensor system can be quickly and easily implemented without introducing contaminants into the controlled environment.

KFCS Crane specializes in providing tailored lifting solutions for clean rooms. The following solutions are available: tandem operation function for simultaneous control of two or more crane systems, synchronization of several crane axes with millimetre accuracy. Different qualities can also be chosen for the model that is completely made of stainless steel.