Environmental contaminants such as dust, fingerprints, particles, vapors, microorganisms and bacteria are important considerations during the development of space instruments and components, and these stray dust particles or fingerprints can damage or disable scientific instruments.

Quantitatively designed aerospace equipment cleanrooms have extreme requirements for airborne particulate control. Air Modular Filtration Systems (MFS) consist of portable HEPA filtration units designed to filter cleanroom air to eliminate work-grade contamination. The design is universal and allows the use of single or multiple units. MFS consists of HEPA supply air, return air (HEPA or non-HEPA) and full side ESD walls. Since the unit filters clean air in a clean room, the standard ISO 8 (Class 100,000) area will remain below ISO 7 (Class 10,000). The main goal is to achieve continuous laminar flow velocities of 90 +/- 30 ft/min. Keeps particles moving in zones throughout space, with particle swarms below ISO 7 (level 10,000) for activity. The design achieves this through fully open ceiling access and allows for a modular design to accommodate changing requirements and equipment placement. Sidewall design depends on specific customer requirements or personnel entry points.

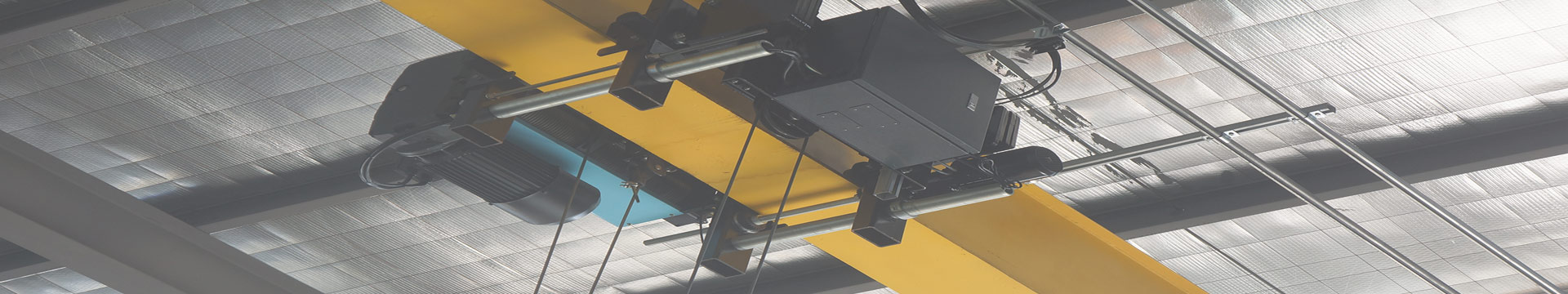

KFCS non-standard design and production of cleanroom cranes for aerospace equipment workshops, welcome to inquire about plans and quotations.

0086-13390692151

0086-13390692151