Introduction of Class 1000 Clean Rooms

Some of the primary applications that Class 1,000 clean rooms are used for include inspection, patterning and integration tools like non-contact profilometry, flip-chip integration, thin-film deposition, and laser micromachining. As a result of these diverse applications, Class 1,000 clean rooms are utilized in industries including pharmaceutical, scientific research, medical, electronics, semiconductor, food processing, and industrial manufacturing.

However, since Class 1,000 clean rooms are lower level clean rooms, they may have all of the requirements for certain higher-grade applications. For instance, they may not have an air shower at the entrance and may not require individuals to wear special shoes, although some still do; everyone wears a head-to-toe bunny suit to keep skin and hair particles out.

Some of the many contaminants that Class 1,000 clean rooms are used to keep out include human hair, dust particles, paint, air conditioning debris, lint, skin flakes, and lubricants. The most common sources of these contaminants are people, tools, fluids, the facility, and the product that is being manufactured. In order to keep these pollutants out and meet the standards of strict regulations, acrylics, steel, stainless steel, aluminum, and polycarbonate are generally the materials that are used to fabricate the walls of Class 1,000 clean rooms.

Temperature control and electrostatic discharge control are just a few of the other options that are also possible in this class of clean room.

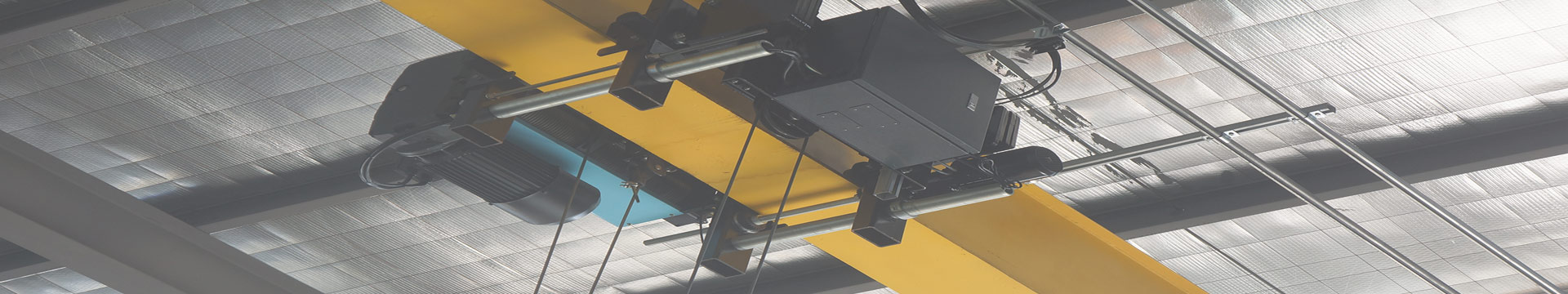

KFCS manufactures clean room cranes and provides Class 1000 Clean Rooms cranes. Welcome to inquire about design plans and inquiries.

0086-13390692151

0086-13390692151